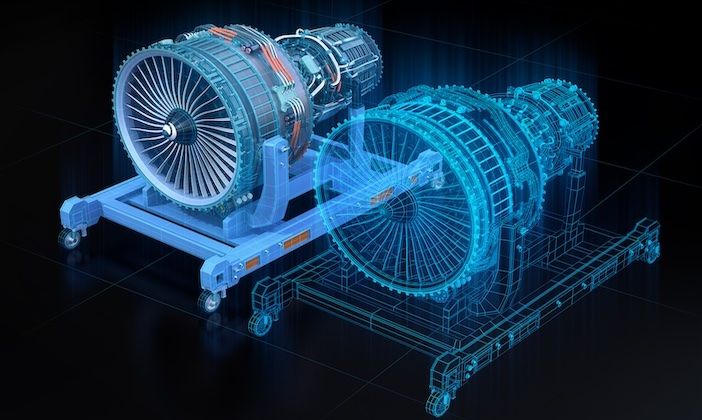

The aviation industry is embracing the digital twin – a live, virtual replica of an aircraft, component, or system, updated in real-time. This isn’t just a 3D model; it’s a dynamic digital counterpart enhancing every stage of aviation.

The Digital Twin’s Journey in Aviation:

- Design & Development: Virtual testing identifies flaws early, cutting costs and speeding up new aircraft creation.

- Manufacturing: Monitors production for quality control and efficiency, preventing costly errors.

- Operations & Flight: Real-time data from flying aircraft feeds the twin, offering unparalleled insights into health and performance for optimized flights and troubleshooting.

- Maintenance: Enables predictive maintenance, anticipating failures before they happen. This means precise repairs, minimal downtime, and significant cost savings. Technicians can even simulate repairs virtually.

- Training: Powers highly realistic flight and maintenance simulators.

Key Benefits Taking Flight:

- Enhanced Safety: Predicting issues before they occur.

- Increased Efficiency: Optimized operations and reduced downtime.

- Cost Reduction: Fewer prototypes, streamlined maintenance, and efficient operations.

- Improved Decision-Making: Data-driven insights across all operations.

- Sustainability: Less fuel consumption and more efficient resource use.

The digital twin is revolutionizing aviation, promising safer, more efficient, and sustainable skies. Its potential is limitless as technology advances.